Overview

Sycare is supplied in “nest” and “tub” configuration, sterilised by both gamma rays and “EtO”

The devices are thoroughly inspected and all stages of the production process are supervised and monitored. The production process is highly automated, thus ensuring quality as well as the respect of delivery times, maintaining cost efficiency. The entire production process is monitored remotely.

Our machines and production equipment, placed in the ISO7 clean room, have been designed and studied by the Engineering department of Althena Medical, specifically to be easily and quickly fitted. We are able to switch quickly and without errors from one volume to another, from one customisation to another, ensuring speed, quality and flexibility.

All Sycare assembly and packaging stages take place in an ISO 7 clean room.

Given the very low activation force of the plunger in the barrel, Sycare is especially suitable for liquids with high or very high viscosity. Sycare has also been developed in 0.5 ml, 3 ml e 5 ml versions.

Sycare has been tested on various filling machines, always proving to be a reliable and “machinable” product, i.e. it can be filled using automatic filling machines.

Sycare has been tested on various filling machines, always proving to be a reliable and “machinable” product, i.e. it can be filled using automatic filling machines.

Several autoclaving tests were carried out on Sycare with pressures up to 3.5 bar. All the results of these tests are available and can be consulted upon request.

Why choose Sycare

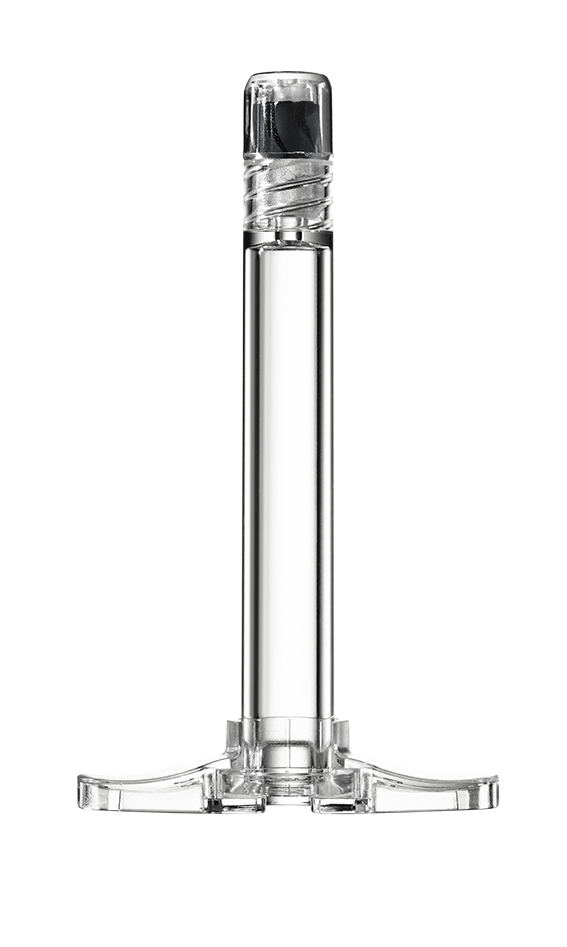

The Sycare family of syringes to be pre-filled has been conceived and designed to enhance the product, making it stand out from its competition.

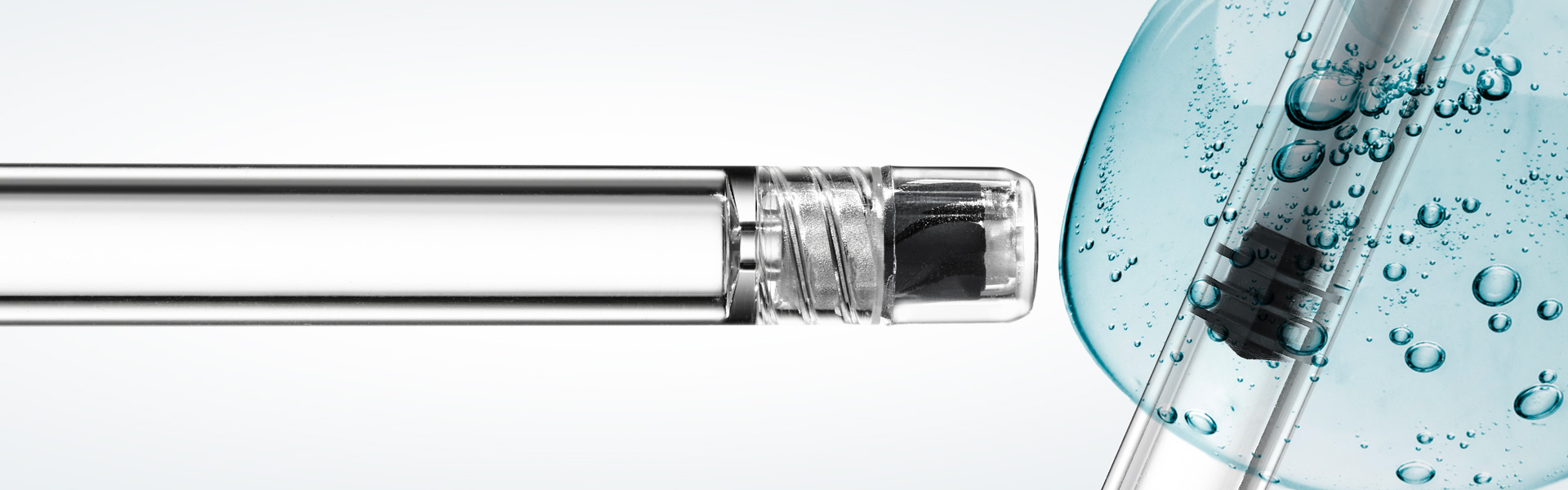

In fact, it is the only one on the market with a transparent COP cap. It has a very low activation force and maintains transparency even after sterilisation.

The customer’s logo can also be affixed. It can be customised in terms of shape, volumes and colours, so as to be easily identifiable. All this makes Sycare an exclusive product that enhances and highlights the customer’s brand.

Airtightness is guaranteed for over 3 years from filling. Methylene blue test reports available upon request.

Why we created Sycare

Sycare is a family of pre-refillable syringes in COP, which has been designed and created to grant a more viable option on the evolving pre-filled syringes market.

Sycare stands out thanks to:

- its durable and sturdy design which prevents cracks and breakages;

- the fact that remains transparent even after being sterilised;

- the low frictional force of the plunger in the barrel;

- its completely transparent COP cap.

Sycare is suitable for use in the following fields:

- aesthetic medicine;

- orthopaedics;

- ophthalmology;

- general medicine.

Other benefits

- available in sizes up to 6.5 ml and greater. Off-specification volumes on request;

- highly extensive and complete technical documentation supplied;

- almost frictionless screw cap: it unscrews easily, without releasing microparticles;

- brandable: the customer’s logo can be placed on the finger grip;

- rigid rod: suitable for high viscosity liquids;

- highly automated and remotely controlled production process;

- technical and after-sales assistance;

- extensively tested in the laboratory, reports available on request;

- protected by two international patent applications;

- rigid, sturdy and ergonomic finger grip;

- secondary packaging can be performed on request.

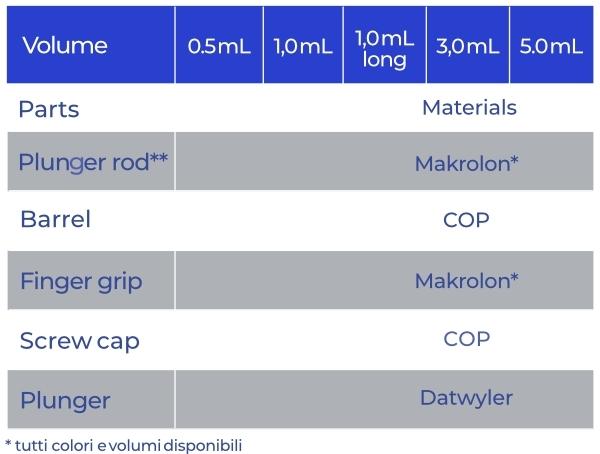

Technical specifications

Wide range of colours and volumes

Screw cap

- Easy to screw and unscrew

- Low friction between rubber and syringe tip

- Tested superior sealing power

- Patent pending

Plunger rod

- Durable and rigid design

Design

- Reinforced to prevent cracks

- Easily recognisable

Why we make COP barrels

- Transparent like glass, but less heavy

- Low internal friction

- Easy to shape

- Breakage and leak resistant

- No alkaline ion leaks

- Constant PH values guaranteed

Why choose Sycare in COP

Because Sycare has been designed to be made in COP. All technical choices have been made thinking about the peculiarities of COP, which is a material with great potential but which also presents some risks, such as the formation of cracks or colour changes.

Why choose a syringe with an tamper-evident system?

Like food products (which always have a tamper evident system), an anti-tampering system is also highly desirable for products in the beauty and pharma sectors. This is what emerges from a survey among the physicians we work with (more than 300) and many of them confirm this.

Why choose our Sycare Secure (SySe) tamper-evident syringe

Our tamper-evident system, protected by an international patent application, is truly tamper-proof. In fact, the cap has to be broken in order to tamper with it. The system was conceived and designed to prevent the coupling between the safety and the cap and between the safety and the barrel from being reached. Therefore, the only way to remove the safety that assures the syringe cannot be tampered with is to open it. And once opened, it cannot be repositioned, as it is now broken.

Tamper-evident system with label.

Another tamper-evident system is our label. It has been designed to be wrapped around the barrel and the cap. And it has a breakable area, which guarantees control that the solution in the device cannot be tampered with.

Request a free consultation and a free sample

Leave your details to be contacted by one of our experts and:

- receive a free sample;

- receive a report on the test and trails carried out in external laboratories to support the performance of our products;

- receive product validation reports;

- receive technical data sheets;

- know what scientific studies we performed;

- pallet size, MOQ, shipping time etc.

- Find out the exhibitions and events which we will attend.